Campaign advertising

design

At Ticketmedia, I helped businesses of all sizes, from small start ups to global corporations, deliver successful visual campaigns. In the medium of ticket and roll advertising.

Regular clients included McDonald's, Burger King, Subway, Wickes, GOV.UK, E.ON and all major UK bus companies (First Group, Arriva, Stagecoach), among many others.

Whether creating designs from clients written briefs, reformatting or updating artwork, I adhered to strict brand guidelines & company policies.

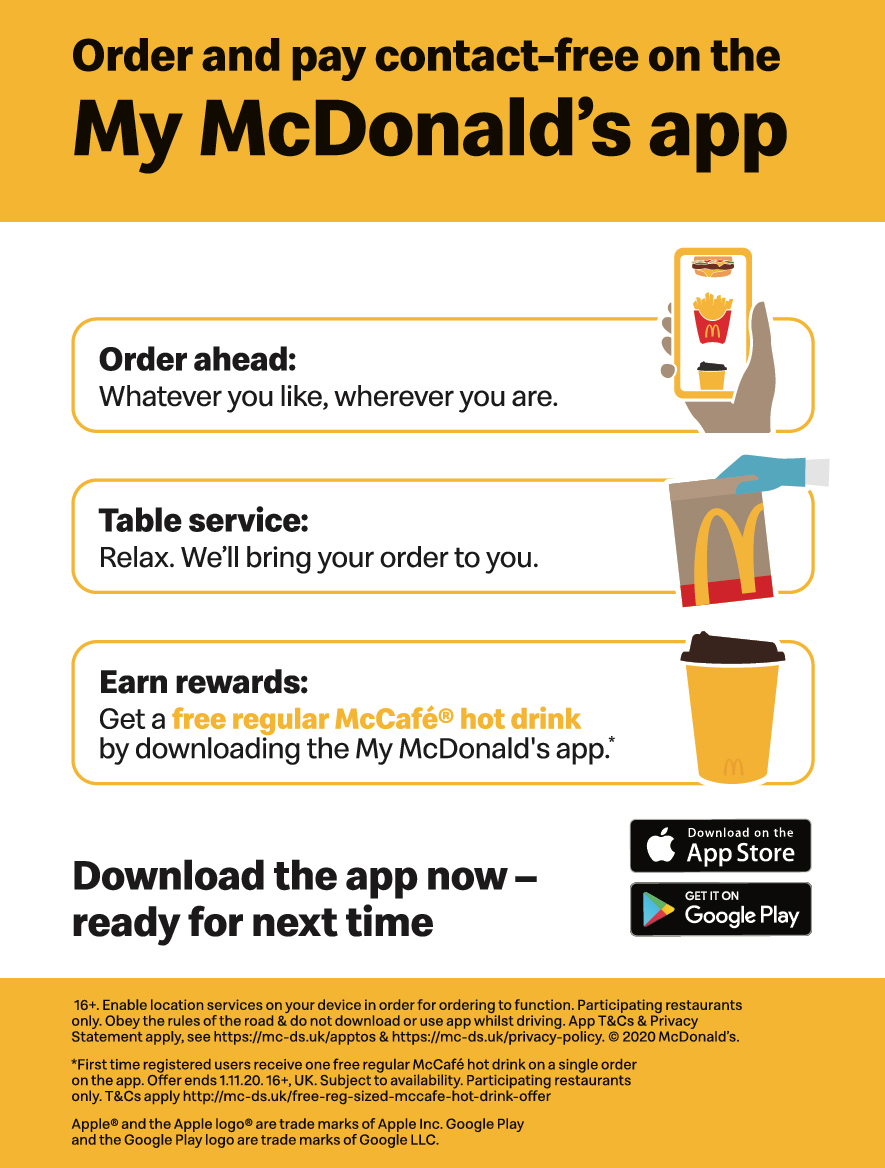

McDonald's EPOS roll artwork, to be used nationwide as part of a large multi format campaign. Reworking assets to best fit the print dimensions for the EPOS format.

DFDS bus roll campaign. Creating the artwork from brand guidelines, image assets and a written brief from the client.

Selco EPOS roll for a specific location. Part of a larger, nationwide, two part campaign to advertise new stores, followed by the specific opening date. Reworking assets and colours for print.

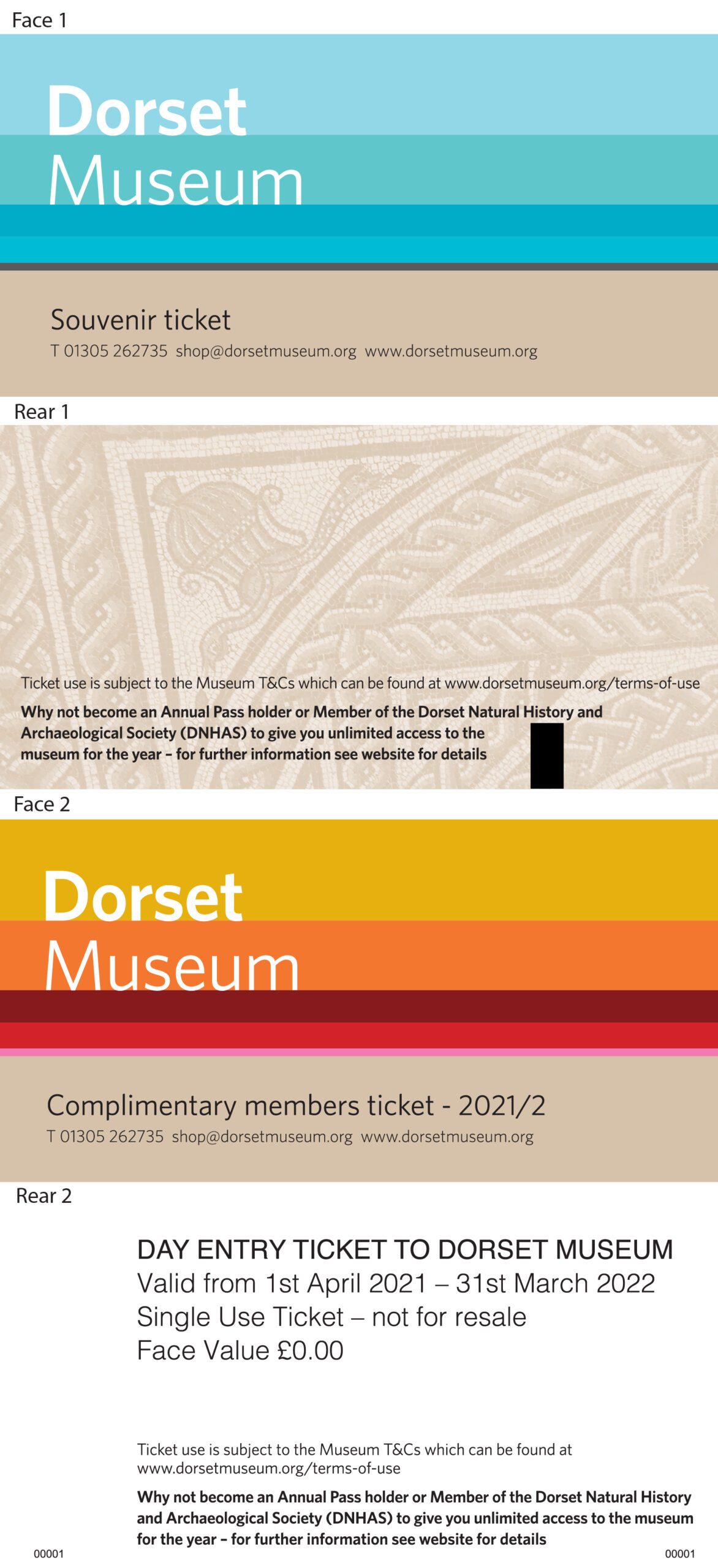

Dorset museum tickets, to be used for entry. From a supplied brief, brand guidelines and image assets, I created the layout, design and colour profile for the tickets, ensuring the design wouldn't interfere with the supplied sensor position.

Windermere jetty museum bus roll campaign. For a local bus campaign; I created the final design from a written brief. Some visual assets were supplied, but due to low quality it was necessary for me to recreate these as vector based files before they could be used.

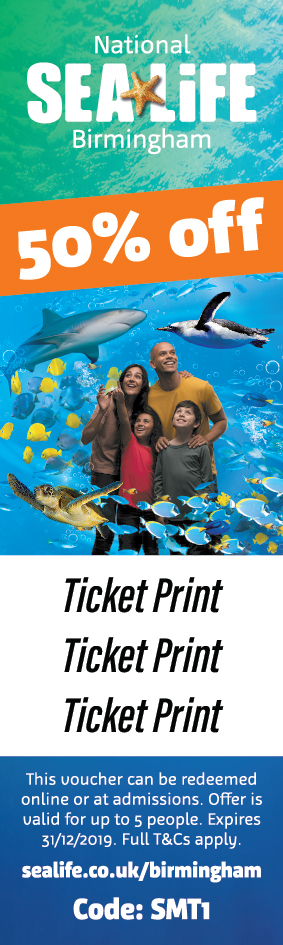

Sea life centre Birmingham bus roll advertising campaign. From a supplied brief and assets used for the larger format designs for the campaign, I was tasked with creating the bus roll artwork. I had to ensure my design was in keeping with the existing campaign visuals.

The above work was produced whilst I was head of creative services at ticket media. In an average month I would be responsible for designing, reformatting or updating anywhere between roughly 50 and 100 of these jobs before creating the accompanying job folders, flexographic printing plates, physical proofs and anilox reference sheets.

I would then assign these jobs to the relevant flexographic presses and respective printers, for manufacture. It was also my responsibility to sign off the initial print samples, checking they passed all quality checks, before the main print run could begin.